Gas Transmission & Compressor Station Noise: Measurement, Modeling & Mitigation

Noise Mitigation Recomendations

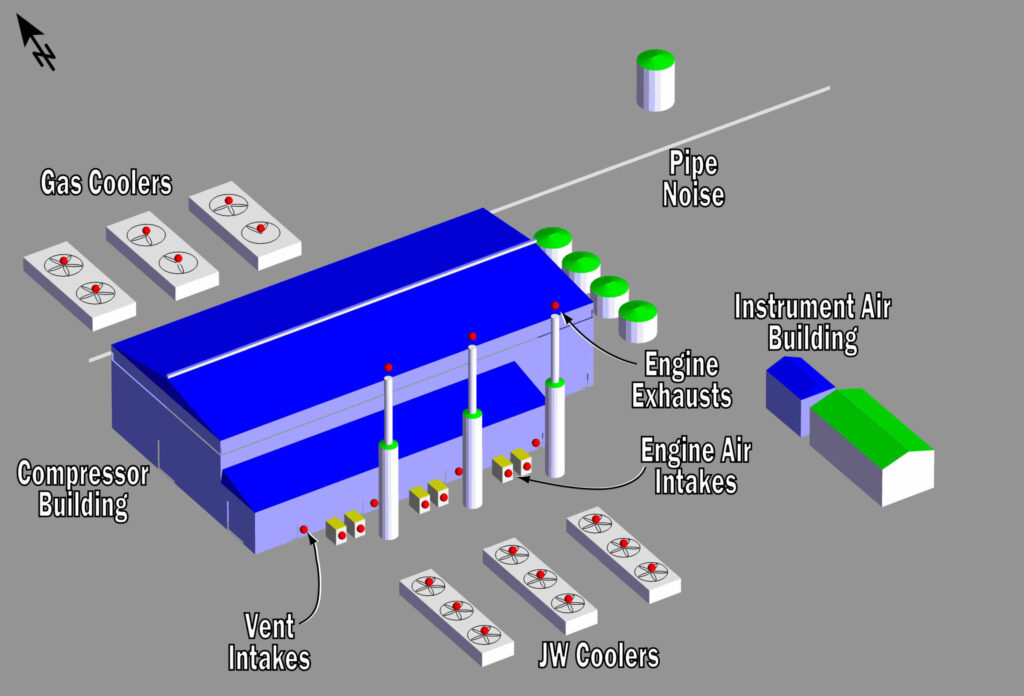

Gas transmission and compressor stations are essential components of the natural gas infrastructure, but they can generate significant noise. They can be a single unit or a combination of units, depending on the need. The noise originates from various sources, including the compressors themselves, as well as the engines, and the flow of high-pressure gas through pipelines and valves. The resulting sound can range from high-frequency tonal noises to low-frequency hums and vibrations, which can travel considerable distances. These noise emissions can have both occupational and environmental impacts.

Specifically, within compressor stations, the mechanical operation of the compressors themselves, driven by large engines, produces substantial noise. Additionally, the turbulent flow of natural gas through piping, particularly at points of pressure reduction, creates aerodynamic noise. This can result in both airborne noise and vibrations that propagate through the ground. The control of this noise is a significant concern for operators, with strategies including the use of silencers, acoustic enclosures, and specialized valve trims to mitigate the impact on both workers and surrounding communities.

In our experience, gas transmission line and compressor station owners want their operations to be safe and consistently meet all applicable noise limits. While the added cost for noise mitigation is not ideal, the added cost of not mitigating is much higher.

Noise Measurements and Modeling of Gas Compressor Stations

Establishing Baseline

Gas compressor station noise management starts with baseline measurements to assess pre-operational sound levels. A 3D noise model, using manufacturer data and prior measurements, then predicts operational noise to ensure compliance before operation.

Mitigation Strategies

If modeling predicts non-compliance, mitigation strategies like silencers, enclosures, or barriers are simulated and implemented, targeting major noise sources.

Validation and Ongoing Compliance

Operational noise is measured post-construction to ensure ongoing compliance, with further mitigation if necessary.

Noise from Gas Pipelines

Noise considerations for gas pipelines primarily focus on the above-ground components, such as valves, piping, and metering, as the buried sections produce minimal operational noise. These exposed elements typically emit high-frequency sounds that, while potentially irritating, tend to dissipate quickly. Mitigation strategies commonly involve lagging, which combines sound-absorbing and dense mass layers to reduce noise transmission. In instances of excessive valve noise due to design flaws, replacement may be necessary. Although buried pipelines are generally

Noise Mitigation Recomendations

Based on our comprehensive noise assessment and modeling, Cerjan Acoustics develops tailored noise mitigation strategies to address specific project requirements. Our recommendations encompass a range of solutions, including:

- Noise Barriers

- Land Use Planning

- Acoustic Enclosures

- Lagging and scilencers

Frequently Asked Questions

Why do they need to operate gas compressor stations?

Gas compressor stations are essential for the efficient and safe transportation of natural gas through pipelines over long distances. Their primary function is to maintain pressure and flow in order to reach its destination. Compressor stations also “boost” the pressure to allow the gas to travel efficiently to homes, businesses, and industrial facilities. These station are necessary as natural gas pipelines can be hundreds or even thousands of miles long.

How loud are gas compressor stations?

The loudness of a gas compressor station depends on several factors with the primary one being distance to the unit. Within 25 feet of a gas compressor or near the exit of the exhaust, the noise levels can exceed 100 dBA. Local noise regulations will define how loud these stations can be at a noise-sensitive receiver. This will result in the station owner installing noise mitigation, which generally includes exhaust silencers, enclosures, and noise barriers. A common residential noise limit in the U.S. is 55 dBA during the daytime and 50 dBA at night, but because these stations operate 24 hours per day, the design would be to meet 50 dBA both daytime and nighttime.